|

|

|

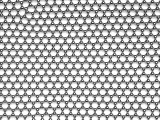

Bubble raft

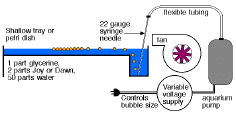

A bubble raft is produced using an aquarium pump to blow soap bubbles through a syringe needle. (Companion Demonstration 5.1 and Figure 5.2)

|

|

Prepare raft

The non-directional attraction between soap bubbles models the non-directional attraction between metal atoms, and a close-packed array is formed. A slider is used to apply stress to the array. (Companion Demonstrations 5.1and Figure 6.4)

|

|

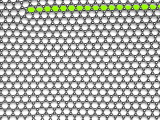

Grain boundary

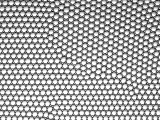

Bubbles in a raft form grains of close-packed arrays with various orientations relative to each other. As the raft is stressed with the slider, dislocations move into and out of the grains and their boundaries. (Companion Demonstration 6.2 and Figure 6.9)

|

|

Liquidmetal¨ and stainless steel

Stainless steel spheres dropped on Liquidmetal® (left) and stainless steel (right) demonstrate loss of energy into grain boundaries. Liquidmetal is an amorphous alloy of titanium, zirconium, nickel, copper, and beryllium.

|

|

Maraging steel, Liquidmetal¨, titanium

Stainless steel spheres dropped on maraging steel (left), Liquidmetal® (center) and titanium (right) demonstrate loss of energy into grain boundaries. Maraging steel contains Fe, Mo, Cr, and Ni. Liquidmetal is an amorphous alloy of titanium, zirconium, nickel, copper, and beryllium.

|

|

Nucleation and growth

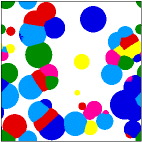

Crystallization occurs by nucleation and subsequent grain growth.

|

|

Bubble zip

Stressing a bubble raft causes dislocations to move through the array. (Companion Demonstration 6.2)

|

|

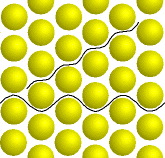

Bubble zip yellow

The previous movie is repeated with the dislocations now highlighted in yellow. The atoms comprising the "extra" half-planes change as the dislocations move. (Companion Demonstration 6.2)

|

|

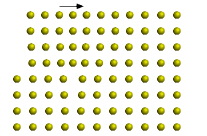

Dislocation

An animation of the motion of a dislocation through a metal. (Companion Figure 6.8)

|

|

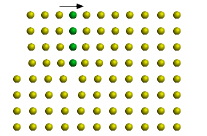

Dislocation green

The previous animation is repeated with the dislocation now highlighted in green. The atoms comprising the "extra" half-plane change as the dislocation moves. (Companion Figure 6.8)

|

|

Caterpillar

The movement of a caterpillar by the motion of a dislocation down the length of the caterpillar.

|

|

Corn picture

A line dislocation found in corn-on-the-cob. (Companion Figure 6.7)

|

|

Slip planes

Which slip direction requires less energy? Close-packed slip planes facilitate the bending of a metal. (Companion Figure 6.3)

|

|

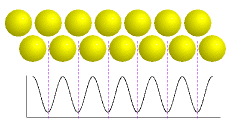

Slip plane energy

Energy vs. displacement for movement along a slip plane. (Companion Figure 6.2)

|

|

Metal stretch

Stretching a metal causes movement along slip planes until catastrophic failure occurs.

|

|

Indium bending sound

Slowly bending a sample of indium metal causes a "click" as the dislocation-assisted movement of atoms exceeds the speed of sound in air. (Companion Demonstration 6.3)

|

|

Rug dislocation

Which requires less energy? Lifting a rug, carrying it and laying it down; or pushing a wrinkle through it? The rug is analogous to a plane of atoms and the wrinkle to a dislocation. (Companion Figure 6.10A)

|

|

Rug hardened

When multiple wrinkles become tangled, motion is more difficult. This is analogous to work hardening in a metal. (Companion Figure 6.10B)

|

|

Copper work hardening

A piece of copper wire can be annealed in a flame and work hardened by bending. (Companion Demonstration 6.4)

|

|

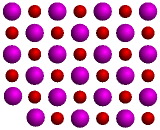

Ionic conductor

This animation illustrates electrical conductivity in an ionic solid through vacancy-assisted cation motion. (Companion Figure 6.13)

|

|

Rn lab

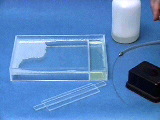

The defects in a plastic disk caused by alpha particles from radon decay are enlarged by etching with NaOH and then viewed under a microscope. The number of etch pits in a given area of the plastic disk can be used to determine radon level in the location sampled. Adjusting both focus and polarization are important in identifying the spherical etch pits. (Companion Experiment 6)

|